What was previously allowed only to kings, in today's world perfectly survives in the mansions of successful and successful people. We are talking about the use of gold and gold jewelry in the decorative decoration of interior spaces, furniture, as well as the exterior of the architectural elements of buildings. Of course, not parts made of pure metal are used for this, but a special technology - gilding with gold leaf, originating in very distant times.

Precious decorative element

Gold is a very expensive material for use in large projects. Therefore, in ancient times, people began to use the ductility of this metal to save it for decorative purposes. Take, for example, Pharaoh's stretcher. They look massive and cast in pure gold. But in fact it is covered with gold leaf with a very thin layer.

Thanks to the development of industry, the improvement of technologies and tools and the advent of many new materials, anyone can afford to surround themselves with a luxurious decor. True, this possibility is due to the use of substitutes, such as potal or gold leaf acrylic.

Methods of obtaining and scope of the material

So what is gold leaf? This term came to us from ancient times hidden in the depths of civilization, and meant “surface”, “covering”. It was transformed into the concept of “leaf” from the word “face”, “facial”. If you do not plunge into the jungle of linguistics and other sciences, then gold leaf has acquired its name precisely because of the method of use - coating surfaces “from a sheet”.

Decorative structures covered with this type of material give beauty, elegance and luxury to both furniture and rooms. But the use of this type of finish is fraught with great difficulties, as it involves the use of very thin pieces of material. Their thickness varies from 13 to 67 thousandths of a millimeter, and working with them requires some preparation by the master and the use of special technologies and tools.

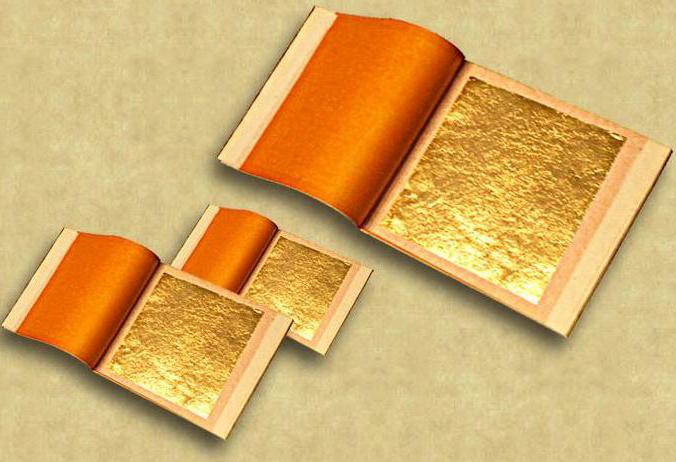

Gold leaf is obtained using the “chipping” technology, in which a piece of metal that is heated and rolled to a certain thickness is transferred to the “beating”. Previously, this process took place in several stages and required a huge amount of human strength and time. Now it is computerized and mechanized, but its high cost is still quite high - out of two and a half kilograms of precious metal it turns out just a kilogram of leaf. Leaflets of finished material are placed between the pages of a booklet of a certain format. The weight of such books can be from one and two tenths of a gram to six grams. It should be noted that for external use this material is used weighing from two and a half grams. Gold leaf, the price of which depends on the sample, can be purchased in many specialized stores ranging from 36-40 dollars per book.

Gilding Technologies

The technology of applying decor can be divided into two main types. The first is when gold leaf is transferred to a surface previously coated with an oil or varnish composition. It is called matte. In this form, the surface is matte and not particularly elegant. But this method of application is more stable and is used when performing both decorative internal work on various materials, and external.

Another type - polymer (glue), provides for the imposition of gold leaf on the surface treated with water-glue mixtures. This is the way in which the maximum gloss of a gilded surface is achieved. But it is possible to apply it only when performing decorative decoration indoors and mainly for the decoration of wood or plastic products.

Features gilding with gold leaf

This is the complexity of working with the material itself. Indeed, even the lightest draft can lead to the loss of more than one hundred dollars if the weightless and expensive gold leaf falls under its influence. Also gold leaf cannot be taken simply by hands - its weightlessness and fragile structure will instantly affect. It will turn into dust in the hands of a woe-master. Therefore, they work with it with a special tool and having at least simple handling skills with such gentle and expensive material.

Imitation gold

Substitutes are called to reduce the cost of the process of decorating for precious metal. It can be both gold on silver - a double, and gold on a copper base - talma. The high cost of the metal itself also contributed to the origin of such imitators of a gilded surface, such as a potal – silver alloy with aluminum, as well as tin disulfide, most often used for gilding wood and gypsum.