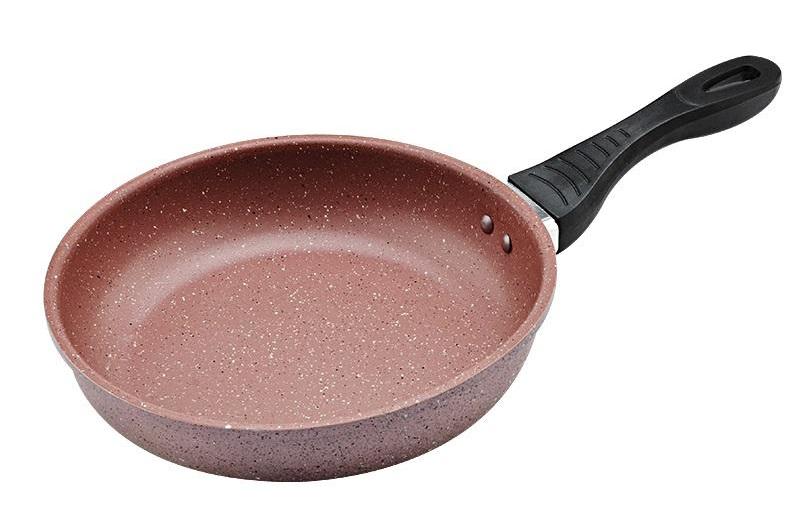

Many housewives love aluminum pans because of the advantages of this cookware - good heat conductivity and low weight. Such products are distinguished by their design features. Particularly in demand are aluminum pans with non-stick coating. The types and rules of product care are described in the article.

Description

Aluminum cookware is lightweight, quickly laundered, has an affordable cost. But this metal, although not prone to corrosion, is sometimes very "active". In such dishes, it is forbidden to say jam, cabbage soup, fruit-based compotes.

Both the taste of the dish and the dishes suffer - aluminum becomes dark and loses smoothness. But frying is a slightly different process, and different demands are placed on pans. According to reviews, these products are convenient in preparing a variety of dishes.

Cooking Methods

Non-stick coated aluminum pans are made using various technologies. It depends on the production method in which culinary processes the dishes can be used, and in which not:

- Stamped is a cheap way. The process involves cutting and stamping products from aluminum sheet. Work can only be performed with a small metal thickness, so the dishes will be thin-walled. During bending, aluminum undergoes deformation, and such damage worsens thermal conductivity and reduces temperature resistance. This capacity is very light, convenient to use, but can not withstand prolonged and frequent heating. Usually the dishes are reinforced with a steel disk, which allows to extend the life of the device.

- Forged - a method of pressing on forging devices. The metal is heated to plasticity, the containers are pressed into the desired shape. Forging makes aluminum stronger, so an aluminum pan with a non-stick coating based on forged metal will last longer than a stamped one. The technology helps to obtain products with thin walls and a thick bottom. Typically, steel plates fit into the bottom, as this cookware is designed for induction cookers.

- Cast aluminum cookware - metal is poured into molds and pans of the desired configuration are created. The metal cannot be deformed, and retains its properties. The material provides uniform heating, durable products. But this technology is energy-intensive, so the dishes are more expensive. The bottom of the cast metal tank is reinforced with anti-deformation discs. The dishes are used on different stoves: induction, gas, electric.

According to reviews, aluminum dishes are in demand among many housewives. It is valued for its practicality, durability and neat appearance. Save the product allows proper care.

Non-stick coating

Aluminum pans with non-stick effect differ not only in the production method, but also in the coating method. It is thanks to the last property that many choose such dishes. According to the coating material, there are the following options:

- Teflon. The coating functions perfectly, but it should not be exposed to sharp objects, such as a metal sponge. Products serve no more than 2-3 years. It is forbidden to heat containers above 200 degrees, because this destroys the coating and its substances interact with food. Teflon coating is applied at a temperature of 400 degrees, which ensures complete removal of impurities. And tetrafluoroethylene itself is a neutral polymer.

- Ceramic coating is a polymer composite material with particles of silicon. The latter provides resistance to elevated temperatures, so the tank can be heated up to 450 degrees. The advantage of the dishes is the possibility of cooking with a small amount of oil: the material is smooth, so it spreads in a thin layer. Sharp temperature changes, mechanical friction, and impacts are harmful to the ceramic coating. Tanks are not suitable for induction cookers. Products last about 2-3 years.

- Marble is a teflon coating with marble chips. It can be applied in several layers. Multilayer pans can last up to 25 years. The coating cools slowly, is not afraid of temperature changes. The downside is considered to be a lot of weight - the product is slightly lighter than the cast iron. And the price of the dishes is high - if there is a thickened bottom, the cost will be at least 2,000 rubles. An excellent option is a model of cast aluminum with a thickness of 6 mm and a five-layer coating. Cooking is done without oil. But periodically it is necessary to lubricate clean dishes with oil and treat with a napkin.

- Titanium coating. Thanks to him, non-stick aluminum grill pans last 10–25 years. Titanium is neutral, not afraid of temperature changes, and because of the smoothness of the dish, you can cook with the addition of a small amount of oil. The price of such products is high.

- A diamond coating is a layer of Teflon, but with the addition of diamond dust. Due to this, the durability of the coating is extended to 10 years or more. This surface is more difficult to scratch, easy to clean. The dishes can be washed in the dishwasher.

Coating Methods

According to experts, the coating method is also important. It depends on the method of manufacturing the dishes:

- On stamped containers, the coating is applied on the blanks - before stamping. During bending, the coating is damaged, which affects its quality and durability. Such dishes are light and affordable, but they do not serve much.

- On cast aluminum containers, a layer is applied by spraying. Non-stick material is sprayed with a spray gun, and then sintered at elevated temperature. Pre-cooked dishes are processed to ensure high-quality adhesion of the material to the metal. Therefore, the layer is distributed evenly and fully retains its properties. Cast pans can be used for different plates.

pros

Aluminum pans have the following advantages:

- Speed and uniformity of heating. The material conducts heat well, and cast aluminum does not have the drawbacks that metal receives during forging or stamping. This cookware has a quick and uniform heating.

- Corrosion Resistance Aluminum in air is instantly coated with an oxide film. Therefore, products are not able to rust.

- The strength of the material due to the thickness of the walls and bottom. Therefore, aluminum is not afraid of mechanical factors.

- Heating up to 400 degrees can be performed.

- In the presence of a thick bottom there is an improved storage effect. Cookware cools more slowly, so you can extend the cooking period.

- The metal has no pores, so it’s easy to wash pans from dirt, but the type of coating should be considered. Tableware with a titanium or diamond coating can be washed in a dishwasher.

- Products are durable.

- Cookware can be used for induction, electric, gas stove.

disadvantages

A perfect pan also has disadvantages. The main disadvantage is the cost. Long-lasting dishes are expensive, and if there are thick walls, the cost increases markedly. Not all products are dishwasher safe. It is not worth storing prepared foods in aluminum dishes.

Information about the dangers of an aluminum pan with non-stick coating is not justified. The cost of this type of product does not allow the use of poor-quality coating, as is the case in the manufacture of stamped dishes.

Manufacturers

Aluminum dishes are produced by many manufacturers because of the availability of material. The best companies include the following:

- Tefal. The non-stick coating in the dishes of this French company is of high quality. Products are created using tetrafluoroethylene, which is baked on the surface of products at temperatures above 400 degrees. It is difficult to destroy this coating by heating on a gas stove. The dishes are great for daily use over time.

- Neva-metal. The dishes of this company consist of an alloy - aluminum (88%) and silicon (12%), which ensures durability. The technology of production by injection molding with crystallization under pressure is used. In Neva-Metal dishes, non-stick coatings are fluoropolymers, often a marble composite. Products have excellent quality. Pans are suitable for daily use.

- Rondell. The dishes have a reinforced fused bottom, which improves thermal conductivity and accelerates the preparation of dishes. Non-stick coating based on fluoropolymers, but there is also a titanium option.

- Stoneline. Cast aluminum products have a stone non-stick coating. Dishes can last 20-30 years. It can be washed in a dishwasher; cutlery can be used during cooking.

- Frybest - Pans are ceramic coated. Products can heat up to significant temperatures. You can store food in a pan.

- Ceramacgranit from TVS. The company creates aluminum cookware with a stone non-stick coating, in which granite is used, not marble chips. This combination provides durability, ease of washing and cooking speed.

Almost all of the above firms produce both conventional options and wok pans. The non-stick aluminum pan has an original design. It can be used on ceramic glass hobs and induction hobs. Non-stick coating lasts at least 5 years.

Care

How to clean a non-stick pan? The following recipes are suitable:

- Soda (5 tsp) is dissolved in water (1 liter). The solution should be boiled in a container, and then pour the mixture and remove the remaining burns with a napkin.

- The pan filled with water is brought to a boil. A little liquid soap is added, after which the product is removed from the fire. After cooling the pan, wash it with water.

- It will take ¼ part of the laundry soap, which is grated and poured with water. The mixture is heated in a pan, cools down for 2-3 hours. The remaining fat is removed with a napkin.

- For external purification, special means are used.

Output

Thus, the advantages of this cookware make it popular. According to reviews, a pan with a similar coating will be a great helper in the kitchen. It allows you to cook almost without the use of oil, speed up the process, provides uniform heating.