For the manufacture of many rubber goods, rubberized fabric is used. It has excellent mechanical strength inherent in the textile base. Among the complex of technical properties of the material, it is possible to distinguish low gas, vapor and water permeability, high resistance to aging and abrasion, to various aggressive environments. Quite often it is used when creating goods for home and leisure, for example, rags for washing windows, covers, tents, tents and so on. Its cost is approximately 930 rubles per meter.

The selection of the formulation of adhesives and mixtures for rubberizing the material, as well as the development of technologies should be connected with the capabilities of the entire production process, as well as with the conditions of its maximum efficiency.

A competent choice of the base and the achievement of the required strength are the most important factors that are necessary for the rubberized fabric to last as long as possible.

To date, the range of materials that are suitable for use in the construction of various products has increased. The manufacture of chemical fibers, especially synthetic ones, such as anide, nylon, lavsan, etc., is quite developed. The main advantages of polyamide (kapron) materials (rubberized fabric most often has this basis) are good tensile strength, resistance to severe climatic conditions, the effects of the bulk of existing chemicals, as well as thermal aging.

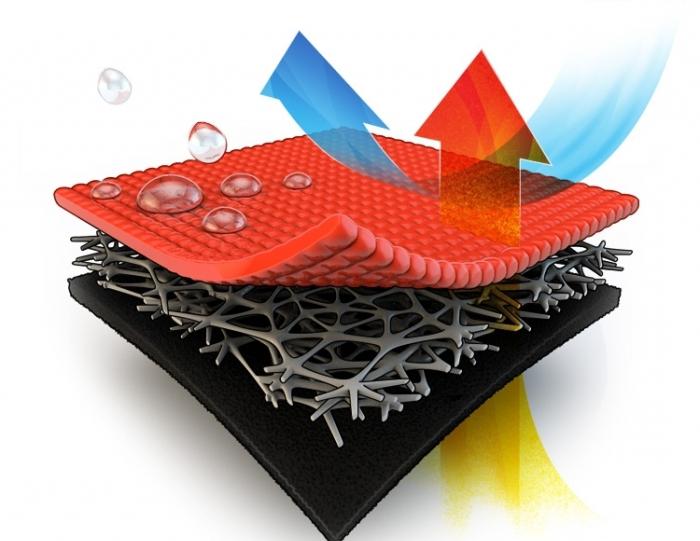

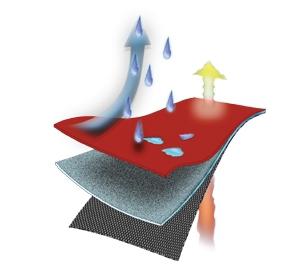

Fluoroelastomer is an impregnation of a material. It is distinguished by heat resistance, in addition, highly fluorinated SC. The rubberized fabric with it is resistant to all kinds of fuel, acids, solvents. It does not respond to various weather conditions, does not burn, does not oxidize, while it can retain its properties in the widest temperature range. Due to its qualities, rubberized fabric, the price of which is low, is used for the manufacture of resistant gaskets, diaphragms and sleeves. The rubber compound is evenly applied on both sides of the material. However, sometimes layers of fabric are combined with special glue.

In addition, a combination is used when applying both the rubber mixture and other coatings, including varnish. Calendaring is used for the manufacture of products and materials, such as rubberized diagonal fabric. The choice is determined by the necessary properties and types. Such materials can be ready-to-use products, as well as mass-marketed goods used to create haberdashery, footwear and outerwear.

Technical rubberized fabrics are balloon materials used to create the shells of airships, balloons and stratostats. They are rubberized with silk or percale, without fail with duplication. In this case, percale up to fifteen layers is applied to silk, which makes the fabric gas-tight. But balloon materials can be from different layers. Their duplication is carried out at a temperature of 45 degrees above zero, which increases the resistance of matter to tangential forces and tension.